Research Centers & Labs

Dive into a world of cutting-edge research facilities, where innovation thrives and boundaries are continually pushed. Explore the diverse array of specialized laboratories and collaborative centers that fuel groundbreaking discoveries across multiple engineering disciplines.

Centers

Director: Hamid Rahai

The Center for Energy and Environmental Research and Services (CEERS) was established in 2003 to conduct interdisciplinary research and development, technology transfer, and education in energy and environmental systems, environmental health, water resources, air pollution and groundwater contamination, and environmental impacts of transportation. The center's advisory board includes representatives from Southern California utility, aerospace, and transportation companies; the ports of Los Angeles and Long Beach; and Long Beach Unified School District. Recent projects include patented innovations in vertical-axis wind turbine performance, mitigation of diesel and compressed natural gas emissions, modeling virus transport on public transportation systems, CFD analyses of particulate matter (PM) deposits in human lungs, and transient transport and diffusion of PM near roads and freeways.

Director: Shadi Saadeh

The (TransGET) was established in 2009 to conduct interdisciplinary research and development, technology transfer, and education in transportation and green technologies. The center is the main platform for providing the for Caltrans and the industry and to perform research in transportation. The center brings together transportation researchers from different disciplines to collaborate on infrastructure research and applications, freight movements, mobility and optimization, technology development, and education and outreach.

Labs

Director: Khalil Dajani

The California Aerospace Technologies Institute of Excellence (CATIE) was established to meet aerospace industry needs for technology growth in CaliforniaÔÇÖs Antelope Valley and Mojave regions. CATIE facilitates a progressive collaboration network platform with the aerospace industry, Air Force Research Laboratory, Mojave Air and Space Port, Naval Air Weapons Station China Lake, and academic research institutions for emerging and advanced technology in space propulsion and responsiveness systems, including ║┌┴¤═° College of Engineering. Find out more

Established in 2014, I-MAT conducts research and development in partnership with industry and state and federal agencies. I-MAT focuses on person-centered design and human system integration, aerospace manufacturing and assembly, rapid prototyping and integration, composite manufacturing, nanofabrication, and systems engineering. The institute provides opportunities for faculty and students to engage in multi-investigator and interdisciplinary R&D. I-MAT's advisory board includes members from Boeing, Northrop Grumman, Raytheon, and automotive design and manufacturing companies.

Contact: Roger Lo

The Analytical Instrumentation Lab is dedicated to material characterization and development of new instruments for biological and chemical analysis.

Major Equipment:

- Nicolet FT-IR Spectrophotometer

- Shimadzu UV-Vis Spectrophotometer

- SRI Gas Chromatograph with FID Detector

- Keithley 2401 SourceMeter

- Zeiss Microscope with Hamamatsu CCD Camera

- Paraytec UV Area Imager

Contact: Panadda Marayong or Praveen Shankar

The houses a CAVE immersive virtual environment system that facilitates interdisciplinary research in human-machine interaction in a dynamic environment. The system consists of room-size four panel displays with 8-camera real-time full body motion tracking. The acquisition of the CAVE system was funded by National Science Foundation Major Research Instrumentation grant (Award number 1626655).

Major equipment:

- VisCube M4 (Visbox, Inc., IL) CAVE VR system with front-projected four panel displays (12ÔÇÖ W x 8ÔÇÖ D x 10ÔÇÖ H)

- ARTTrack real-time full body motion tracking system

- Fully-integrated graphics workstation

Contact: Hamid Rahai

This low-speed, closed-circuit tunnel was donated by Boeing in 1993. The tunnel has a 96.5 X 137 X 305 cm working area, and a 10:1 contraction with a maximum free-stream speed of 90 m/sec. The settling chamber features a honeycomb and six screens for flow conditioning. For speeds less than 50 m/sec, the free-stream turbulence is less than 0.02 percent and the non-uniformity in the flow across the test section is less than 0.1 percent per 5 cm.

Instrumentation available in the tunnel consists of five channels of TSI IFA 100 intelligent flow analyzer with signal conditioner, one channel of TSI model 1050 constant temperature anemometer, a TSI signal conditioner model 1015C, a four channel B&K analog tape recorder which has a maximum frequency response of 15 KHz and a two channels Scientific Atlanta Spectroscope III model SD 345 spectrum analyzer. Also in place are a fast-response Setra Systems manometers and associated Pitot tubes for accurate measurement of mean pressure and velocity and a Newport temperature bridge model 267B and RTD probes for mean temperature measurements.

The tunnel also has a Laser Doppler Velocimetry (LDV) System, a single component, off-axis, forward scatter collection. The clear collection aperture is 40 mm and the transmitter focal length is 300 mm. Fringe separation is 6 microns. The laser used is a Lexel Argon-Ion model 85 with maximum power output of 1 watt. It has photomultiplier and associated signal conditioning electronics and frequency domain single-component signal processor with a PC driver software.

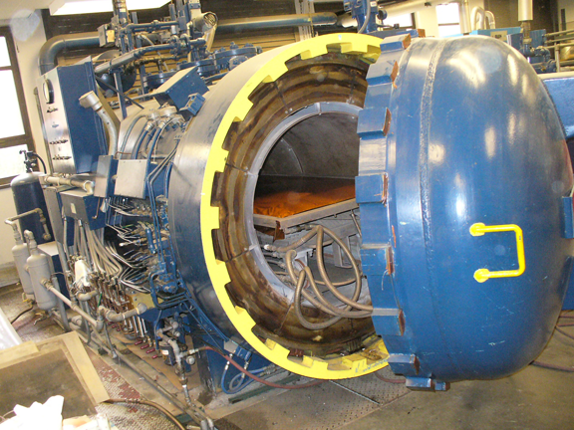

Contact: Yash Singh

This lab contains a sizeable autoclave that can be used for curing the composites that researchers design, cut, stitch, and fabricate. The 5-foot by 3-foot autoclave can accommodate large objects and heat to 800 degrees Fahrenheit and 415 psi.

Contact: Eun Jung Chae

research focuses on the numerical, theoretical, and physical modeling in single/multiphase flows of smart/adaptive propulsions, Unmanned Aerial Vehicles (UAV), morphing wings, and energy conversion systems.

Research Approach:

- Computational Fluid Dynamic (CFD)

- Fluid-Structure Interaction (FSI)

- Reduced Order Model (ROM)

- Theoretical Analysis

Contact: Christiane Beyer or Mahdi Yoozbashizadeh

The DENSO Lab offers ║┌┴¤═° students facilities for computer-aided design, manufacturing, and non-destructive testing. The lab contains an assembly robot, a Computer Numerical Control (CNC) milling machine with the ability to machine parts precisely, and 3D printers to rapidly prototype three-dimensional solid objects of virtually any shape from a digital model. Stored nearby is a plasma cutter used to precisely cut steel and other metal materials of different thicknesses.

Major equipment:

- Airwolf 3D printer

- Artec 3D scanner

- CNC Haas mill

- CNC mill simulators (three)

- MarkForged Mark One 3D printer

- Objet30 3D printer

- Orbital drill center

- Plasma cutter

- Polar 3D printer

Schedule: M-F: 9 a.m.-4 p.m.

Contact: TBD

The Dynamics and Control Lab focuses on:

- Automation

- Robotics

- Manufacturing

- Time-delay systems, and

- Other technologies.

Major equipment:

- Cart-inverted-pendulum setup

- Parallel robot

- Cart-seesaw setup

- Robotic arms

- Rotary-inverted pendulum.

Contact: Hamid Rahai and Shahab Taherian

This lab is equipped for aerodynamics, bio-fluids, and computational fluid dynamics (CFD) research.

Contact: Shadi Saadeh

Contact: Emel Demircan

The research projects range from musculoskeletal modeling to robotic control. HPRL has received grants from DENSO, the National Science Foundation, and the National Institutes of Health and collaborates with various departments and institutions to engage in interdisciplinary research.

Major equipment:

- Force feedback haptic device

- Kinova and Optitrack robotics equipment

- Motion-capture equipment

- Miniature threaded inline load cell

- Robotic arm and hand

Hours: M-F 9 a.m.-5 p.m. and by appointment

Contact: Daniel Whisler

The specializes in understanding dynamic material and structural behavior when subject to extreme environments such as shock, impacts, or blast loads. Experimental and numerical testing for high strain, high strain rate survivability, blast mitigation, and impact resistance.

Major equipment:

- High-strain compressed gas impactor

- Low-strain pendulum impactor

- Drop tower

- High speed camera

Contact: Hamid Rahai

This large-scale testing facility provides equipment for static, fatigue, and creep tests. The lab, which has supported NASA and Boeing research programs, contains 11 Instron servo-hydraulic testing frames (ranging from 22- to 110-kip capacity) with computer-controlled thermal chambers capable of temperatures from -80 to 700 degrees Fahrenheit. The Instron Lab also has humidity and thermocycling chambers.

Contact: Vahid Balali

Major equipment:

- Alienware Laptop (high configuration)

- HTC Vive VR system

- Laser scanner

- Magic Leap VR headset

- Microsoft HoloLens mixed-reality headset

- Oculus Rift VR headset

- Samsung 360 camera

Currently under construction, this lab will provide students and faculty a facility to explore this growing construction specialty.

Contact: Roger Lo

The Microfabrication Lab is dedicated to photolithographic processes and 3D printing for developing and fabricating microfluidic chips that find various applications at the interface of biology, chemistry, and engineering.

Major Equipment:

- Class 10,000 Cleanroom

- WS-400Bz-NPP-Lite Spincoater

- Dyne-A-Mite Surface Treater

- CTC 3D Printer

- MiiCraft 3D Printer

- 3D Potterbot 2.5 3D Printer

Hours: TBD

Contact: Ehsan Madadi

Our group aim is developing new physics-based models and numerical algorithms for predicting the large scale multiphase and complex fluids flows in broad areas of fluid mechanics, such as energy and the environment. The foundation of our research is at the scientific interface of Computational Fluid Dynamics (CFD) and multiphase flows. The focus is on disperse multiphase flows (often reacting flows) with a continuous phase (gas or liquid) surrounding one or more disperse phases (e.g., particle, drops, or bubbles).

Hours: TBD

Contact: Sara Moghtadernejad

The pursues interdisciplinary and multidisciplinary research directions in Chemical Engineering. Dr. Sara Moghtadernejad studies processes and phenomena involving fluid and powders that depict phase changes and have multiple states. Her research arises from practical applications, with the aim of solving challenging and contemporary industrial issues. MFL is a result-oriented laboratory and is equipped with state-of-the-art tools to closely reproduce real-life conditions and to design various interesting experiments. Those are followed by distinct numerical and statistical analyses to verify experimental observations and to provide solutions, enhancements, and corrections.

Hours: M-F 9 a.m.-6 p.m.

Faculty advisor: TBD

The lab focuses on:

- Multiscale/multiphysics modeling

- Integrated computational/experimental approaches for next generation material design

- Application of material science and solid mechanics in advanced manufacturing.

Hours: M-F: 9 a.m.-6 p.m.(by appointment)

Contact: Ehsan Barjasteh

The Polymer and Advanced Composite Laboratory specializes in developing and characterizing new lightweight materials and processes for applications in aerospace, biomedical, automotive, and other related industries. In particular, the research lab focuses on:

- Out-of-Autoclave processes (VBO, VaRTM, RTM, RFI)

- Automated polymer and composite manufacturing

- Nanomaterial

- Multifunctional materials

This research lab contains state-of-the-art advanced manufacturing equipment for:

- Resin transfer molding

- Injection molding

- Hot press

- Differential scanning calorimeter

- Dynamical mechanical analyzer

- Rheometer

Faculty advisor: Mahdi Yoozbashizadeh

The Beach Rocket Lab acts as a central hub for rocketry research on the California State University, Long Beach campus. Located in the Engineering Technology Building, the lab is equipped and supported with the advanced fabrication machinery and tools necessary to develop liquid rockets, as well as support hybrid and solid rocketry.

Faculty advisor: Joseph Kalman

The (SPACL) focuses on understanding the physics and chemistry of ignition, combustion, and decomposition of energetic materials, solid propellants, and other fuels/oxidizers. Traditional and novel experimental techniques are used to probe both gas-phase and condensed-phase reactions. These measurements, in conjunction with complementary modelling efforts, provide insight into how to improve performance or improve safety of combustion applications.

Major equipment:

- Photron Mini AX-100 high-speed camera

- Infinity K2 long-distance microscope

- Iradion Infinity Series CO2 laser (120 watt )

- National Instruments compact DAQ

- Strand burner (under construction)

- Miniature slab burner (under construction)

- Solid fuel opposed flow burner (under construction)

Hours: M-F 9 a.m.-5 p.m.

Faculty advisor: Navdeep Singh Dhillon

The employs high-speed optical and infrared imaging techniques to experimentally study and improve complex thermal-fluids phenomena. Research areas of interest include boiling, evaporation, condensation, renewable energy technologies, desalination, electronics cooling, and thermal management in mechanical & aerospace systems. The experimental and theoretical work is complemented by numerical and CFD analysis of processes and systems using tools such as Python, Matlab, OpenFOAM, StarCCM+. 4)

Major equipment:

- High-speed infrared camera (ImageIR 8320)

- High-speed optical camera (Fastcam SA-5)

- Boiling chamber

- High-power DC supply

- Refrigerated/Heating circulator (F25-HE)

Utilizing the latest virtual reality technology, the MetaCenter expands ║┌┴¤═°'s research, teaching and problem-solving into the Metaverse.